The aluminum extrusion process involves shaping aluminum by forcing it through a die with a specific cross-sectional profile:

Process

-

Preparing

Preparing

-

Cutting

Cutting

-

Extrusion

Extrusion

-

Tempering

Tempering

-

Cooling

Cooling

-

Finishing

Finishing

1. Preparing the Aluminum Billet

Preheating: An aluminum billet (a cylindrical piece of aluminum) is heated to a temperature of around 400-500°C to make it malleable without reaching a molten state.

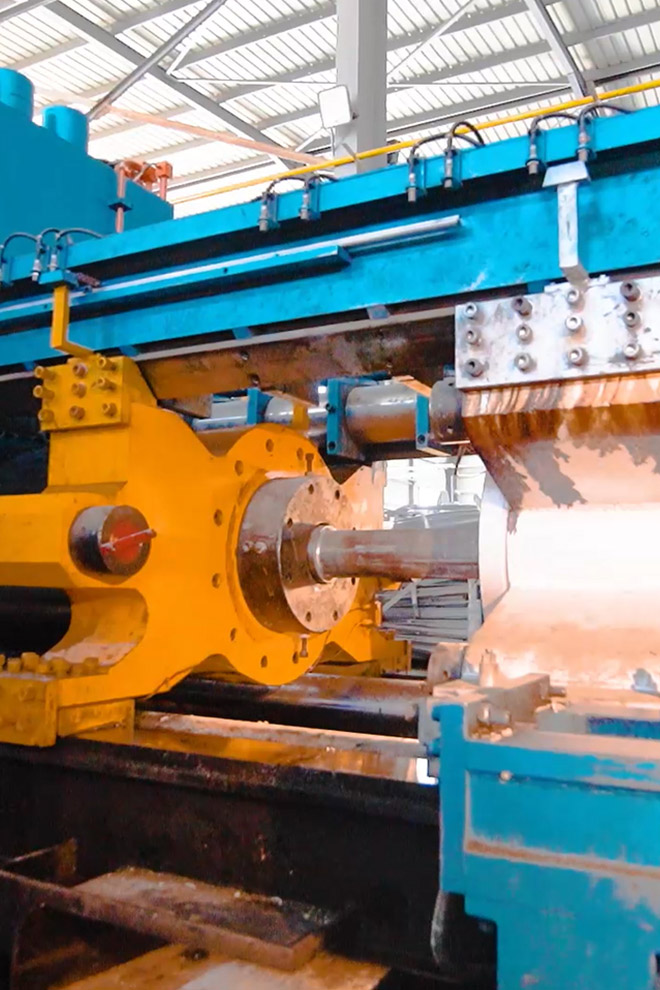

2. Extrusion

Loading the Billet: The preheated billet is placed into a container of the extrusion press.

Applying Pressure: A hydraulic ram pushes the billet into the die. The die has a hole that matches the desired cross-section of the final product.

Shaping: As the billet is forced through the die, it takes on the shape of the die opening, emerging as a long piece with the desired cross-section.

3. Cooling

Once the aluminum exits the die, it’s immediately cooled, usually with water or air, to help it retain its new shape.

4. Cutting

The extruded aluminum is then cut to the desired length, making it easier to handle for further processing.

5. Aging/Tempering

Aging: The aluminum is often placed in an aging oven to enhance its strength through a process called precipitation hardening. This process can take several hours, depending on the specific alloy and required properties.

6. Finishing and Quality Control

Aging: The aluminum is often placed in an aging oven to enhance its strength through a process called precipitation hardening. This process can take several hours, depending on the specific alloy and required properties.