Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum surfaces. This thickened layer provides several advantages, including increased corrosion resistance, improved surface hardness, and enhanced adhesion for paints and adhesives.Proper selection of the anodizing type and finishing options can significantly impact the performance and appearance of aluminum products.

It is the ideal choice for applications where the metal will be exposed to harsh conditions. Anodised aluminium is also more resistant to UV light than powder-coated aluminium, making it a better choice for outdoor applications.

Powder Coating

Powder coating is a dry finishing process that involves the application of finely ground powder to a surface, which is then cured under heat to form a hard, protective coating. This technique is often used on aluminum to enhance its appearance and durability. The powder coating can be applied in a wide range of colors, giving designers more flexibility when choosing finishes for their projects. Powder-coated aluminium is also more resistant to chipping and scratching than anodised aluminium, making it a good choice for applications where the metal will be subject to high levels of wear and tear.

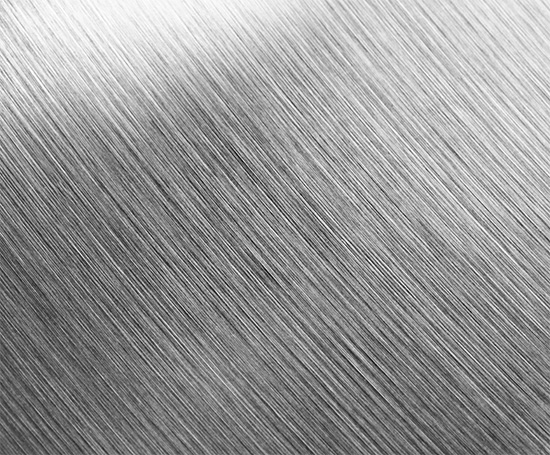

Brushing

Brushing is a finishing process that uses abrasive materials to create a specific texture or pattern on the surface of aluminum. This technique can produce a satin or brushed finish, which is characterized by fine lines or a subtle sheen.